Fire safety is critical in buildings, industrial facilities, and maritime operations. Among the various components of fire protection systems, fire protection valves play a vital role in ensuring reliability, controlling water flow, and protecting lives and assets. Understanding their functions and benefits can help facility managers and engineers optimize fire safety measures.

Ensuring Rapid Water Flow During Emergencies

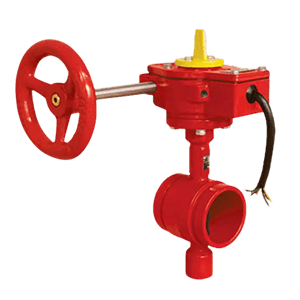

Fire protection valves, such as gate valves, butterfly valves, and check valves, are designed to control and regulate the flow of water or firefighting agents. When a fire alarm is triggered, these valves ensure that water is delivered immediately and at the correct pressure to sprinkler systems, hydrants, or hoses. This rapid response is crucial to suppress fires before they spread, minimizing property damage and saving lives.

Preventing Backflow and Contamination

Many fire protection systems are connected to municipal water supplies. Backflow can cause contamination of clean water, compromising safety. Check valves or non-return valves in fire protection systems prevent reverse flow, ensuring that water only moves toward the fire zone and safeguarding potable water sources.

Maintaining System Integrity

Fire protection valves are built to withstand high pressures, extreme temperatures, and corrosive conditions. Durable materials such as bronze, stainless steel, or cast iron ensure long-term performance without leaks or failures. Regular inspection and maintenance of these valves help maintain system integrity, making sure the system operates reliably when needed most.

Isolating Sections for Maintenance or Damage Control

Valves such as shut-off valves or isolation valves allow certain sections of a fire protection system to be serviced without shutting down the entire network. This is particularly important in large buildings, ships, or industrial plants where complete system downtime can be risky. Isolating sections also allows quick response in case of accidental damage to specific pipeline segments.

Compliance with Fire Safety Standards

Fire protection valves must comply with international and local standards, such as NFPA (National Fire Protection Association), UL (Underwriters Laboratories), and ISO standards. Compliance ensures that the valves meet rigorous quality, performance, and safety requirements. Using certified valves reduces liability, improves safety, and assures regulators that systems are reliable and effective.

Supporting Smart Fire Safety Systems

Modern fire protection systems increasingly integrate smart technologies, such as pressure sensors and automated monitoring. Fire protection valves work seamlessly with these systems, allowing real-time control and remote operation. Automated alerts can indicate valve failure or low pressure, enabling quick corrective action before a fire escalates.

Post time: Dec-25-2025