Actuator valves are essential components in modern fluid control systems, enabling automatic or semi-automatic operation. They consist of a valve, which directly interacts with the fluid, and an actuator, which is the power source that moves the valve. This combination allows for precise, remote control over flow, pressure, and direction without needing manual intervention

1. Pneumatic Actuator Valves

-

How they work: Powered by compressed air to move the valve stem or disc.

-

Advantages: Fast response, simple design, reliable in explosive or hazardous environments.

-

Applications: Widely used in chemical plants, food processing, and marine systems.

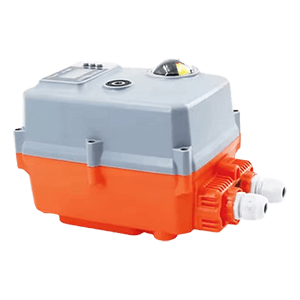

2. Electric Actuator Valves

-

How they work: Use an electric motor to open or close the valve.

-

Advantages: High precision, easy integration with automation systems, no need for a compressed air supply.

-

Applications: HVAC systems, water treatment plants, power generation.

3. Hydraulic Actuator Valves

-

How they work: Use pressurized fluid (oil or water) to move the valve.

-

Advantages: Extremely powerful, suitable for large valves or high-pressure systems.

-

Applications: Offshore platforms, marine engines, heavy industrial processes.

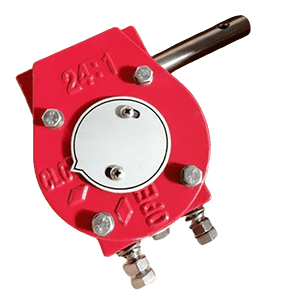

4. Manual Override Actuator Valves

-

How they work: Combine actuator operation with manual handwheel/lever backup.

-

Advantages: Ensure operation during power or control system failure.

-

Applications: Safety-critical systems in oil, gas, and marine industries.

5. Thermal/Motorized Actuator Valves

-

How they work: Operated by temperature-sensitive elements or small motors, often in HVAC systems.

-

Advantages: Compact, energy-efficient, and good for regulating flow automatically.

-

Applications: Heating, ventilation, and air conditioning control.

Post time: Sep-28-2025