What Is a Worm Gear Actuator

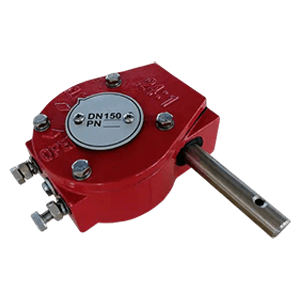

A worm gear actuator is a mechanical device used to manually or motor-operate valves, especially quarter-turn types like butterfly valves and ball valves. It uses a worm-and-wheel mechanism to reduce the required input torque while providing precise control and self-locking characteristics.

Tools & Equipment Needed

-

①Wrenches and socket set

-

②Screwdrivers

-

③Allen keys (if applicable)

-

④Anti-seize lubricant

-

⑤Torque wrench

-

⑥Lifting equipment (for large actuators)

-

⑦Replacement worm gear actuator (with matching specifications)

-

⑧Safety gloves and PPE

Safety Precautions

-

①Isolate the valve: Shut off the process line and depressurize the system.

-

②Lock-out and tag-out (LOTO): Prevent accidental actuation.

-

③Support the valve if it’s large or mounted in a vertical pipeline.

-

④Wear protective gear to prevent injuries from sharp edges or dropped parts.

Step-by-Step: How to Replace a Worm Gear Actuator

Step 1: Mark the Valve Position

-

Record the valve’s open/closed position to reinstall the new actuator in the same orientation.

Step 2: Disconnect the Actuator

-

Remove any mechanical linkages, mounting bolts, or drive shaft couplings.

-

If the actuator is large or motorized, use a hoist to prevent injury or misalignment.

Step 3: Inspect the Valve Stem

-

Check the valve stem for corrosion, damage, or misalignment.

-

Clean the stem and apply anti-seize compound if needed.

Step 4: Mount the New Worm Gear Actuator

-

Align the new actuator with the valve stem and flange.

-

Use the correct bolt pattern and torque per the manufacturer’s specs.

-

For ISO 5211 flanged valves, ensure the drive square fits tightly with the stem slot.

Step 5: Adjust Stop Bolts and Travel

-

Use the travel stop bolts on the actuator to fine-tune the open/close limits.

-

Operate the handwheel to check full open and full closed positions.

Step 6: Test the Assembly

-

Cycle the valve manually to ensure smooth operation.

-

Reconnect motor or control components if using electric or pneumatic override.

Step 7: Final Checks

-

Tighten all fasteners using a torque wrench to spec.

-

Confirm that indicator arrows or dials align with the valve’s actual position.

-

Replace any covers, guards, or tags.

When Should You Replace a Worm Gear Actuator

-

①Excessive backlash or lost motion

-

②Leaks or corrosion on the actuator housing

-

③Inability to fully open or close the valve

-

④Internal gear damage or seizing

-

⑤Actuator size no longer matches system requirements

Why Choose I-FLOW Worm Gear Actuators

At Qingdao I-FLOW, we manufacture high-quality worm gear actuators for marine and industrial applications. Our actuators are:

-

①ISO 5211 compatible

-

②Built for harsh environments (corrosion-resistant coatings available)

-

③Available in manual, motor-ready, and waterproof versions

-

④Supplied with matching mounting kits for I-FLOW butterfly and ball valves

-

⑤Certified to DNV, ABS, CCS, and more for marine use

Post time: Jun-30-2025