Stainless steel is the main material used in its construction. It gives the valve excellent resistance to rust and chemical corrosion. This property makes stainless steel globe valves popular in industries like oil and gas, chemical processing, power generation, water treatment, and marine systems. They can handle aggressive fluids that would damage other valve materials. They can also perform in extreme temperatures and pressure levels without losing strength.

Structure and Working Principle

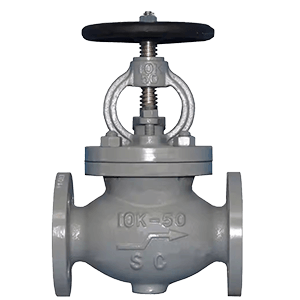

The design of a stainless steel globe valve is simple. It has a body, a bonnet, a stem, a disk, and a seat. When the handle or actuator turns the stem, the disk moves up or down. The disk’s position controls the amount of fluid that can pass through.

The flow inside the valve is not straight. The fluid must change direction when it enters and exits the valve. This path creates a good sealing effect. It also increases pressure loss. Compared with ball valves or gate valves, globe valves always create higher resistance to flow.

Applications in Industry

Globe valves are widely used in pipelines where precise flow control is needed. In power plants, they are installed in steam systems. In chemical factories, they regulate process fluids and acids. In ships, they manage cooling water, fuel oil, and bilge systems. In HVAC systems, they help balance water flow in heating and cooling networks.

Their ability to handle both high pressure and high temperature makes them reliable in critical applications. For example, in offshore oil platforms, stainless steel globe valves are chosen because of their strength against seawater corrosion and their dependable sealing ability.

Advantages of Stainless Steel Globe Valve

One of the main advantages is accurate control. Operators can adjust the valve opening with precision, which makes it useful for throttling applications. Another benefit is strong sealing performance. The valve can prevent leaks even under high pressure. Stainless steel adds durability. It extends the lifespan of the valve, even in harsh environments.

Another point is versatility. Stainless steel globe valves are suitable for water, oil, gas, and steam. They work across a wide range of temperature and pressure conditions. They can be installed in horizontal or vertical pipelines, making them flexible for different layouts.

Disadvantages to Consider

The main disadvantage is pressure drop. Because the fluid changes direction inside the valve, energy is lost in the process. This means pumps may need to work harder to maintain flow. Another drawback is that globe valves require more force to operate compared to ball valves. For large sizes, an actuator is often needed. The valves are also heavier, which can increase installation costs.

Types of Stainless Steel Globe Valves

-

Standard Globe Valve – The most common type, used in general service where flow control and shutoff are required.

-

Y-Pattern Globe Valve – Designed with an angled seat and stem, reducing flow resistance and pressure loss. Suitable for high-pressure service.

-

Angle Globe Valve – Changes the flow direction by 90 degrees, often used in applications where piping layout requires a sharp turn.

Each type has specific advantages, and selection depends on the system’s design and operating conditions.

Post time: Aug-21-2025