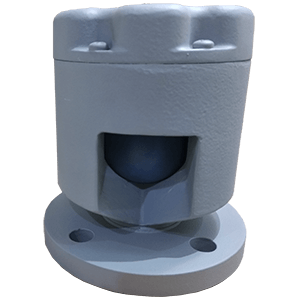

Tank Vent Head and their associated closing devices may look simple on deck, but they play a critical role in ship safety, stability, and regulatory compliance. Neglecting their maintenance can lead to water ingress, cargo damage, corrosion of internal systems, and even serious safety incidents. For shipowners, operators, and marine engineers, proper upkeep of these components is not optional—it’s essential.

Why Air Pipes Matter on a Ship

-

①Vent ballast tanks, fuel oil tanks, fresh water tanks, and void spaces

-

②Equalize internal and external pressure during filling and emptying

-

③Prevent structural damage caused by vacuum or overpressure

In normal operation, air pipes allow tanks to “breathe.” On deck, however, they are constantly exposed to seawater, spray, weather, corrosion, and mechanical impact, making them vulnerable points if not properly protected.

Role of Closing Devices on Deck Air Pipes

-

①Prevent seawater from entering tanks during heavy seas

-

②Protect internal systems from contamination

-

③Maintain buoyancy and stability in extreme conditions

When these devices fail, seawater can enter tanks silently, creating hidden risks that may only become apparent when damage has already occurred.

Key Risks of Poor Maintenance

1. Water Ingress and Tank Contamination

Blocked or damaged vent heads can allow seawater to enter fuel or ballast tanks, leading to:Fuel contamination,Reduced ballast efficiency,Increased corrosion inside tanks

2. Structural Stress and Deformation

If air pipes are blocked:Tanks may experience vacuum or overpressure,Bulkheads and tank walls can deform,Long-term structural fatigue may occur

3. Corrosion and Accelerated Wear

Corroded air pipe heads or closure mechanisms:Lose sealing capability,Become difficult or impossible to operate,Fail suddenly during bad weather

4. Non-Compliance with Class and SOLAS Requirements

Classification societies and SOLAS regulations require:Air pipes to be in good condition,Closing devices to operate correctly,Regular inspection and testing.Poor maintenance can lead to detentions, deficiencies, or failed inspections.

Common Maintenance Issues Found on Deck

-

①Corroded air pipe heads

-

②Stuck or seized float mechanisms

-

③Blocked flame screens or mesh

-

④Deformed closing devices due to impact

-

⑤Paint buildup restricting movement

These issues often develop gradually and are easy to overlook without routine checks.

Best Practices for Maintaining Air Pipes and Closing Devices

Regular Visual Inspections

-

①Check for corrosion, cracks, or deformation

-

②Ensure protective covers are intact

-

③Look for signs of water ingress around tank openings

Functional Testing

-

①Verify float mechanisms move freely

-

②Ensure automatic closing devices seal properly

-

③Test storm valve operation where applicable

Cleaning and Corrosion Protection

-

①Remove salt deposits and debris

-

②Clean flame screens and vent meshes

-

③Reapply protective coatings or corrosion-resistant paint

Scheduled Overhaul and Replacement

-

①Replace worn seals, floats, or springs

-

②Upgrade to corrosion-resistant materials (bronze, stainless steel, aluminum alloys)

-

③Replace outdated designs with class-approved vent heads

Why Preventive Maintenance Saves Costs

-

①Reduces the risk of emergency repairs

-

②Prevents cargo and fuel losses

-

③Extends the service life of tanks and piping systems

-

④Improves vessel safety and operational reliability

In contrast, repairing damage caused by water ingress or corrosion is often far more expensive and time-consuming.

Post time: Jan-27-2026