A needle valve is a precision flow-control valve designed to regulate very small flow rates with high accuracy. It is widely used in systems where fine adjustment matters more than fast opening or closing.

What Is a Needle Valve

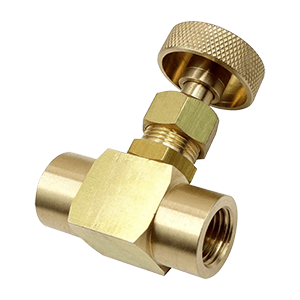

A needle valve is a type of valve used to control flow gradually and precisely.It gets its name from the long, slender, needle-shaped stem inside the valve body.This sharp, tapered stem moves in and out of a small orifice. As it moves, it changes the size of the opening. This allows very accurate control of fluids or gases.

Needle valves are commonly found in:Instrumentation systems,Pressure gauges,Hydraulic lines,Fuel and gas systems,Marine and industrial control circuits

They are not designed for on-off service. They are built for fine tuning.

Main Components of a Needle Valve

-

①Valve body:Houses internal flow passage

-

②Needle (stem):Long and tapered for precise control

-

③Seat:Matches the needle shape to create tight sealing

-

④Handwheel or actuator:Used to turn the stem

-

⑤Bonnet and packing:Prevents leakage around the stem

Each part plays a role in achieving smooth and stable flow adjustment.

How Does a Needle Valve Function

When the handwheel turns:

-

①The stem moves downward to reduce flow

-

②The stem moves upward to increase flow

As the tapered needle approaches the seat, the flow passage becomes smaller.As it retracts, the opening grows gradually.

This design allows:Very slow flow changes.Accurate pressure control.Stable output without sudden surges

Because movement is linear and controlled, operators can make small adjustments with confidence.

Why Needle Valves Offer Precise Control

-

①Tapered stem geometry:Enables fine flow modulation

-

②Small orifice size:Reduces turbulence

-

③Slow stem movement:Prevents sudden pressure changes

This makes them suitable for low-flow systems where stability matters more than speed.

Common Applications of Needle Valves

Instrumentation and Measurement:They control flow to pressure gauges and sensors.This protects sensitive instruments from damage.

Hydraulic and Pneumatic Systems:They regulate fluid or air flow in control lines.

Marine Systems:They are used in fuel lines, lubrication systems, and sampling points where precision is critical.

Chemical and Process Industries:They handle dosing and metering applications.

Needle Valve vs Other Valve Types

Compared to ball or gate valves:

-

①Needle valves are slower to operate

-

②They are not suited for large flow rates

-

③They provide much higher control accuracy

Materials Used in Needle Valves

Common materials include:Brass.Stainless steel.Carbon steel.Monel or alloy steel for corrosive media

Material selection depends on pressure, temperature, and fluid type.

Key Advantages of Needle Valves

-

①Precise flow regulation

-

②Excellent control at low flow rates

-

③Good sealing performance

-

④Stable pressure adjustment

Limitations to Consider

-

①Not suitable for quick shut-off

-

②Not ideal for dirty or particle-laden fluids

-

③Limited flow capacity

Post time: Jan-14-2026