Fire valves are more than just metal parts in a pipeline—they are the first line of defense against fuel-fed fires that can threaten lives, destroy equipment, and endanger entire vessels. In this blog, we explore the importance of fire valves, their functions and marine applications, and how choosing a certified manufacturer like Qingdao I-Flow can significantly enhance a vessel’s safety, compliance, and performance.

What Is a Marine Fire Valve

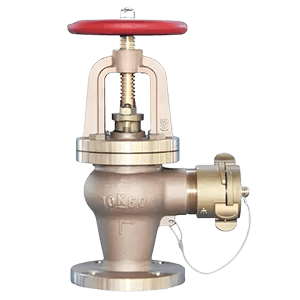

A marine fire valve is a special type of shut-off valve designed to immediately stop the flow of flammable liquids or gases (typically fuel oil or diesel) in case of fire. These valves are placed strategically along fuel supply lines, oil tanks, and critical machinery spaces like the engine room, boiler room, and fuel day tank compartments.

They are equipped with manual, remote, or thermal activation mechanisms so they can shut down the supply lines either by crew intervention or automatically when exposed to high heat.

The Role of Fire Valves in Fire Prevention and Suppression

1. Preventing Fire Escalation

A small fire in a marine engine room can quickly escalate if fuel continues to flow unchecked. A properly installed fire valve can immediately stop the fuel supply, containing the fire and giving the crew a chance to extinguish it before it spreads.

2. Compliance with IMO & SOLAS Requirements

According to SOLAS Chapter II-2 (Regulation 4 & 5) and the International Maritime Organization (IMO) standards, ships must be equipped with shut-off valves for oil and fuel systems to prevent fire propagation. Failure to comply can result in:Detention by port state control.Suspension of class certificates.Heavy fines and insurance claim issues

3. Remote Shut-Off for Safety

Fire valves are designed to be operated remotely from outside danger zones, such as from the emergency control station. This allows crew members to shut down fuel lines without exposing themselves to flames or smoke.

4. Protecting Crew, Cargo, and Vessel

In emergency scenarios, fire valves help to protect:Critical machinery from fire-related damage.Structural integrity of the vessel.Crew safety, allowing quick isolation of hazards.Valuable cargo, especially in tankers or chemical ships

Key Features of High-Quality Marine Fire Valves

| Feature | Function/Benefit |

|---|---|

| Thermal shut-off | Activates automatically at preset temperatures |

| Manual/remote actuation | Enables safe operation during fire or emergencies |

| Anti-corrosion materials | Withstands seawater, salt spray, and oil exposure |

| Fire-tested construction | Complies with ISO 10497 or API 607 fire testing standards |

| Classification-approved | Certified by DNV, ABS, LR, CCS, and other major societies |

Where Are Fire Valves Used on Ships

Fire valves are installed in a variety of critical systems:

-

①Fuel Oil Supply Lines – To isolate flow from day tanks, service tanks, and booster pumps

-

②Diesel Engines – Fire valves are placed near engines to cut off fuel during overheating or fire

-

③Boiler Feed Systems – Valves are used to shut down oil burners

-

④Purifiers and Oil Heaters – Where ignition risk is high

-

⑤Cargo Pump Rooms – Especially in tankers transporting flammable fluids

Marine Classification Society Approvals for Fire Valves

| Society | Country |

|---|---|

| DNV – Det Norske Veritas | Norway |

| ABS – American Bureau of Shipping | United States |

| LR – Lloyd’s Register | United Kingdom |

| BV – Bureau Veritas | France |

| CCS – China Classification Society | China |

| NK – Nippon Kaiji Kyokai | Japan |

| RINA – Registro Italiano Navale | Italy |

| KR – Korean Register | South Korea |

Why Choose Qingdao I-Flow for Marine Fire Valves

As a professional marine valve manufacturer, Qingdao I-Flow produces a wide range of valves designed for safety-critical applications—especially for marine and offshore fire protection systems.

Our Fire Valve Highlights:

-

①DNV, ABS, LR, and CCS certifications

-

②Built to ISO 10497 fire test standards

-

③Body materials: cast steel, bronze, stainless steel

-

④Available with manual, thermal, and remote shut-off options

-

⑤Long service life and corrosion-resistant finishes

Post time: Jun-27-2025