Shut-off valves are one of the most essential components in any piping or fluid system. Whether in marine systems, HVAC, water treatment, or industrial processes, these valves play a crucial role in controlling, isolating, and protecting pipelines. Understanding their purpose and importance helps engineers, technicians, and facility managers maintain system efficiency and safety.

What Is a Shut-Off Valve

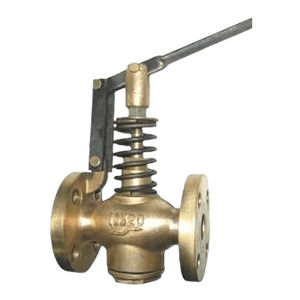

A shut-off valve is a device used to stop or allow the flow of fluid in a pipeline. Unlike control valves that regulate flow, shut-off valves are primarily for isolation purposes. They are designed to provide a full seal, preventing fluid from passing when closed.

Common types include:

-

①Gate valves – ideal for full open or close operation.

-

②Ball valves – quick and reliable for on/off applications.

-

③Globe valves – allow throttling in addition to shut-off.

-

④Butterfly valves – suitable for large diameter pipelines.

Purpose of a Shut-Off Valve

1. Emergency Isolation

In case of leaks, fire hazards, or equipment failure, shut-off valves can quickly stop the flow, preventing damage, injury, or environmental hazards.

2. Maintenance and Repair

Shut-off valves allow sections of a system to be isolated for maintenance or replacement without shutting down the entire operation. For example, in marine systems, specific pipelines like ballast, fuel, or cooling lines can be isolated to perform repair work safely.

3. Safety

By controlling the flow, shut-off valves protect personnel and equipment from overpressure, contamination, or unexpected fluid release. They are a first line of defense in any critical fluid system.

4. System Control and Efficiency

Even in non-emergency scenarios, shut-off valves allow operators to redirect flow, balance pressure, or stop fluid for operational changes, contributing to overall system efficiency.

Importance of Shut-Off Valves

Shut-off valves are not just simple components; they are vital for operational continuity, safety, and cost-efficiency. Their importance can be highlighted in several ways:

-

①Prevention of Catastrophic Failure: Immediate isolation reduces the risk of flooding, fire, or chemical spills.

-

②Minimizing Downtime: Maintenance can be performed on a section of the system without interrupting the entire process.

-

③Protecting Equipment: Prevents pumps, tanks, and pipelines from damage due to backflow or overpressure.

-

④Compliance: In industries like marine, chemical, or water treatment, proper shut-off valves are often mandatory to meet safety standards and classification society regulations.

Best Practices for Shut-Off Valve Selection and Use

-

Choose the right type: Ball valves for quick shut-off, gate valves for larger pipelines, globe valves for throttling.

-

Consider material compatibility: Bronze, stainless steel, or cast iron depending on fluid type and temperature.

-

Follow manufacturer instructions: Pay attention to flow direction and installation orientation.

-

Regular inspection and maintenance: Ensure sealing surfaces and actuators function correctly.

Post time: Dec-18-2025