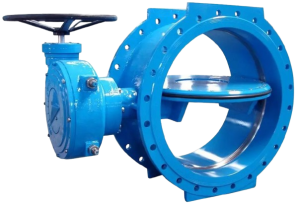

What differentiates butterfly valves from other types of valves is their design, specifically the eccentricity of the valve’s shaft in relation to the valve’s seat and disc. The degree of eccentricity impacts how the valve operates and how it handles different flow control conditions. In this article, we will explore the difference between single, double, and triple eccentric butterfly valves and how each one is suited for specific applications.

1. Eccentric Butterfly Valve

A butterfly valve operates using a disk or disc that rotates to regulate the flow of media through the pipe. The term “eccentric” refers to the positioning of the valve’s shaft relative to the valve’s body and seat. The more eccentric (offset) the shaft is from the seat, the more force is applied to the seal as the valve opens and closes, improving its sealing performance and allowing the valve to handle higher pressures and more demanding applications.

Eccentric butterfly valves are typically classified into three categories: single eccentric, double eccentric, and triple eccentric, each with varying degrees of offset in the shaft design. Let’s dive deeper into the differences

2. Single Eccentric Butterfly Valve

Design:In a single eccentric butterfly valve, the shaft is positioned slightly off-center in relation to the valve seat. This slight eccentricity allows the valve’s disc to rotate in a way that prevents excessive wear on the valve seat during operation.

Functionality:The main benefit of a single eccentric design is that it reduces the friction between the disc and the seat during opening and closing, minimizing wear and increasing the valve’s lifespan. As the valve opens, the disc begins to move away from the seat in a cam-like motion, creating a wiping action that prevents the valve seat from becoming damaged.

Applications:Single eccentric butterfly valves are used in systems that require low to medium pressure control and where high sealing is not as critical. They are often found in applications like ventilation, air handling systems, and non-critical flow applications.

Advantages and Disadvantages

- Simple design with fewer components.

- Cost-effective compared to double and triple eccentric valves.

- Suitable for low-pressure systems where absolute tightness is not as crucial.

- May not provide a tight seal under high-pressure conditions.

- Limited performance in demanding or fluctuating flow environments.

3. Double Eccentric Butterfly Valve

Design:A double eccentric butterfly valve features two offsets. The first offset is the shaft positioning (similar to the single eccentric design), but the second offset is in the disc itself. The disc is positioned at an angle that further optimizes the sealing and reduces wear on the seat.

Functionality:The additional eccentricity in a double eccentric butterfly valve enhances its sealing performance. As the valve opens, the disc’s edge lifts off the seat at an angle, reducing friction between the seat and disc. This design creates less contact pressure on the valve seat during operation, resulting in a more robust seal and longer service life. This design is more suitable for medium pressure and higher performance applications.

Applications:Double eccentric butterfly valves are often used in water treatment plants, pumping stations, HVAC systems, and oil and gas applications, where moderate flow control and better sealing performance are required.

Advantages and Disadvantages

- Improved sealing and reduced wear compared to single eccentric valves.

- Better performance in medium-pressure systems.

- Higher durability and longer lifespan.

- Slightly more complex and expensive than single eccentric valves.

- Not as efficient in high-pressure and high-temperature applications.

4. Triple Eccentric Butterfly Valve

Design:This unique design minimizes friction further and provides an exceptional seal by ensuring that the disc does not come into contact with the seat until the valve is completely closed.

- The first offset is the position of the shaft relative to the center of the disc.

- The second offset is the angle of the disc’s face.

- The third offset is the conical shape of the seat.

Functionality:The triple eccentric design improves the sealing by ensuring that the disc only makes contact with the seat during the final stages of closure. This allows the valve to maintain a tight seal under very high pressures and extreme temperature variations, making it ideal for critical applications where leakage cannot be tolerated.

Applications:Triple eccentric butterfly valves are typically used in high-pressure, high-temperature, and high-cycle applications. They are commonly found in industries such as oil and gas, chemical processing, power generation, and marine applications, where precision, durability, and safety are critical.

Advantages and Disadvantages

- Superior sealing performance under high pressures and extreme conditions.

- Minimal wear on the seat and disc, leading to a longer lifespan.

- Reliable for critical applications where leakage is unacceptable.

- Excellent control in demanding applications with high flow or varying pressures.

- More expensive due to the complex design.

- Requires more maintenance in comparison to simpler valve types.

- Heavier and bulkier, making installation more challenging in some applications.

Post time: Feb-08-2025